Plique á jour Samples

Below is a sample I made when coming back to university. This Plique á Jour sample is the most technically challenging one I have done up to this date due to the size of the cells. I managed to fill the cells successfully and timed and made note of how long I had the piece in the kiln and what happened to it this time.

After the piece was complete, I noticed that the metal had curved due to the heat and the tension. I decided to test flattening the piece as the metal was soft due to being annealed in the kiln to see what the outcome would be. As predicted, the enamel cracked. For some reason, I liked the cracked enamel effect, but this played a risk in the enamel falling out. I then tested if I reheated the piece, would the glass fuse back together? This was successful. There was still a crack within, but I knew if I heated it for longer, it would fuse, I liked this imperfection, I believe there is something beautiful about it. This is something I am going to bear in mind going forward.

Piece after adding enamel

Piece after flattening and the enamel is cracked

Piece once re fused in the kiln

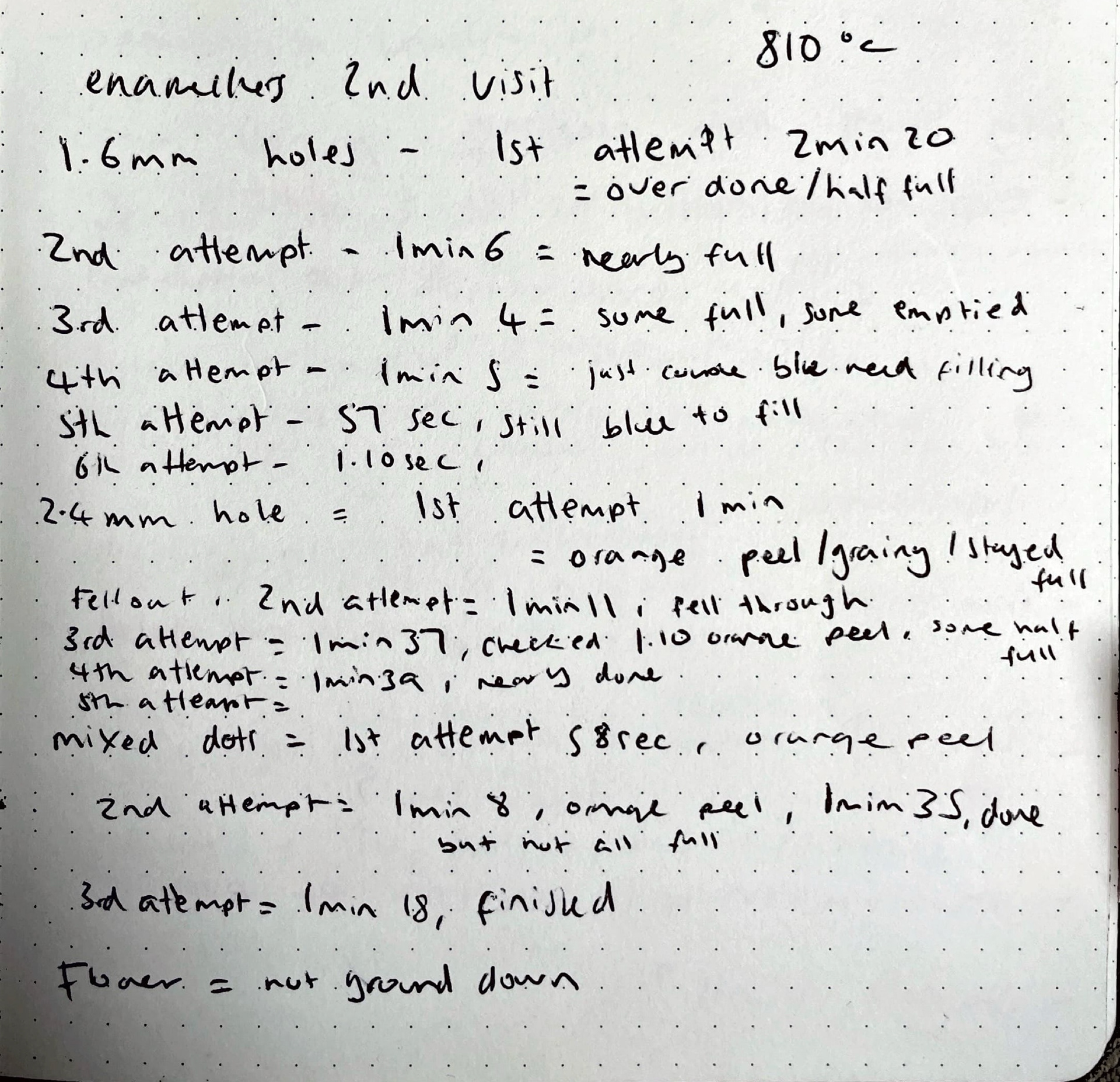

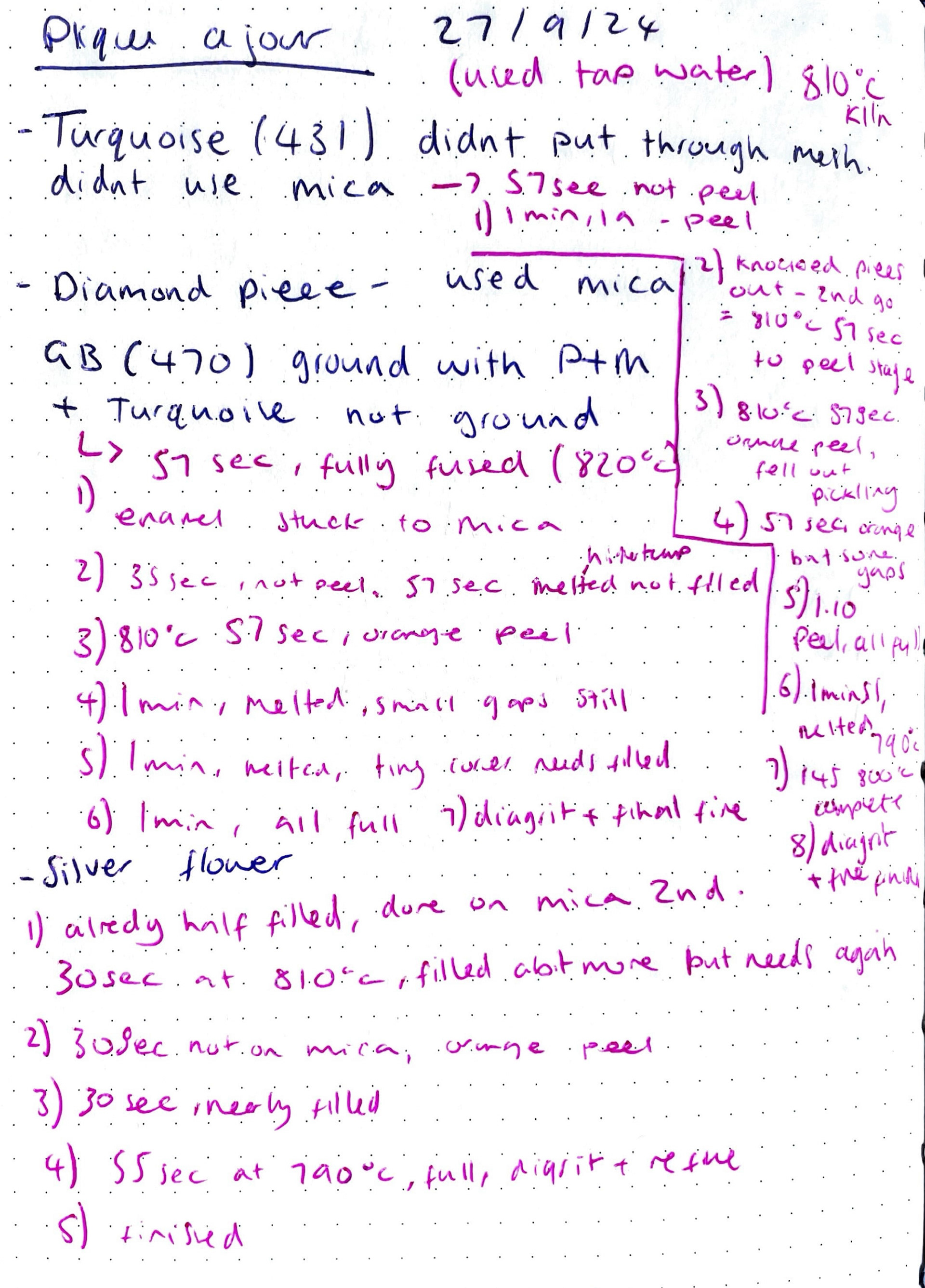

Technical notes

Technical notes

Research notes

For my sample piece for Beta Project and GNCCF, I wanted to create a piece showing the techniques I want to use in my end project. I decided to use a design from the geometric patterns from Masjid I Jami Mosque in Isfahan, Iran, as a simple and quick pattern to use but still relatable. I wanted to make a 3D piece to give the full effect of the light going through the piece to show the stained glass qualities to it.

I researched different ways people do Plique á Jour on YouTube as there isn't much information out there on the finer details of how to do the technique if something goes wrong. I realised it is very much trial and error and finding what works best for you. I had previously used methods using just water with the enamel, also using Mica as a backing to help keep the enamel in place. The method I was going to try with this sample piece is one I saw on a YouTube video, which involves mixing the enamel with Klyre Fire, which is a bonding agent used in enamelling which will burn away when fired.

I started by piercing out the pattern in copper. I used a 2mm thick copper sheet. I then filed grooves in the metal for me to be able to fold this later on. Following this, I prepped my enamels by grinding them down and washing them. Then, I started to fill cells with the first colour. At each firing, I turned the piece over to try and work with gravity. I continued doing this until all the cells were full. As this is copper, the metal oxides at each firing, meaning flakes of the oxidisation were at risk of falling into the enamel, which it did. A lot of people Plique á Jour with silver. However, this isn't an option for me at the moment to practice with.

Once all the cells were filled, I used a diamond grit and alundum stone to grind down the glass outside of the cells. Followed by using a range of emery paper to also give the metal a smooth finish. I then re-fired at a high temperature to re-shine the enamel. The issue with this, then, is the oxidisation again, whereas, with silver, this wouldn't be a problem.

Tools needed for Plique a Jour

Pattern from masjid i jami in Isfahan, Iran

Pierced out

First enamel added

Nearly filled cells

After being filled and grinded down

once re fired, can see the flakes inside the enamel

finished piece once clean

Bent and binding wire added

Imperfections after this firing

After this, I then attempted to evenly bend the metal into a box shape, knowing this would crack the enamel. I knew adding the enamel when the piece was 2D would be easier due to gravity and surface tension. However, I was also aware that now, after folding the metal and re-firing to solder and re-fusing the cracks, it would be a risk and difficult.

I used binding wire to hold the piece in place and used hard solder because the kiln would be hot enough to melt the solder, but less of a chance for it running too much and falling out. Unfortunately, this didn't go well; the binding wire created marks in the glass, and it didn't solder together. Some of the cells also fell out. This was frustrating, but it was the risk I took. I did like the marks left by the binding wire as they reminded me of scars. I decided to clean the piece up again and re-fire to make the glass transparent again. Followed by using emery paper to light sand the metal to get some shine to it.

Process Reels

After we were tasked with creating a process reel, I made two more reels to continue showing the process of my Plique á Jour sample piece.

Filigree samples

The other technique I aim to use in my work is Filigree. I started creating a sample of this. The form of this had no particular relation or meaning I just liked it and wanted to practice the technique itself before putting my take on it. I started drawing out the design and using this as a guide to bend the square wire. I made the wire square using the rolling mill. Once the frame was soldered, I decided to try to fill the piece with zig-zag filigree wire. I didn't get to do this part due to deciding to focus only on the Plique á Jour sample for GNCCF rather than putting too much pressure on myself. I also tried to make a filigree piece, basing the design off another Persian pattern and had a play around with this but also didn't take this any further.

Square wires cut to size

Finished Sample - Beta project

I was overall happy with my finished sample for Beta Project/GNCCF. I was proud of achieving this even though it was far from perfect. I did push my skills, and considering it was the first time I did something like this, I believe I did quite well. I learnt a lot in the process of this, which I will be taking forward with what I make using this technique in the future. I did have to come to terms with its imperfections and this being shown to the public however, it was a sample piece, so it isn't expected to be perfect.

As well as this, I do want to research polishing methods using copper, as I wasn't able to shine the copper to a finished standard without affecting the enamel. There will be a way around this, but I am yet to find out. I also want my final pieces to be made in silver and gold plated so the oxidisation problem won't happen with this, therefore I don't want to spend too much time on research on polishing the copper as this won't be reflected in my final piece.

Going forward, I know I need to practice my technique with filigree and get a better understanding of how I have with Plique á Jour. I did learn a lot from the little sample I did and will keep this in mind when next practicing this.